Flywheel / driveplate — removal and installation

Removal

1. Raise the vehicle and support it securelyon jack stands, then refer to Chapter Manual transaxle and remove the transaxle.

2. If the vehicle is equipped with a manualtransaxle, remove the pressure plate and clutch disc (see Clutch and driveline). Now is a good time to check/replace the clutch components and pilot bearing.

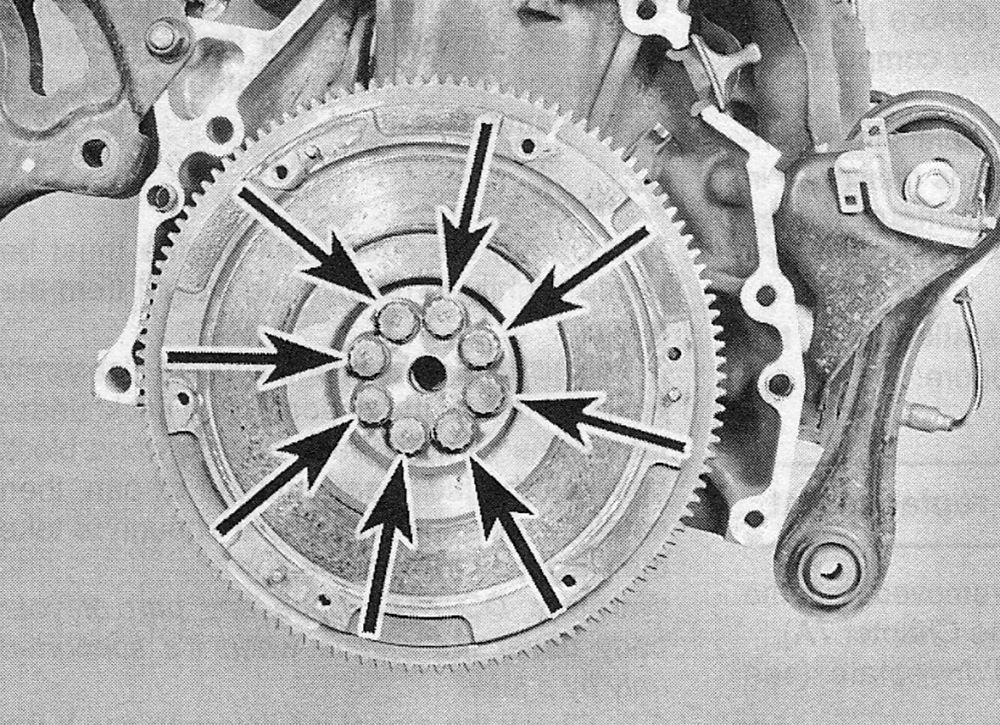

3. Remove the bolts that secure the flywheel/drive plate to the crankshaft (see illustration). If the crankshaft turns, wedge a screw-

driver in the ring gear teeth (manual transaxlemodels), or insert a long punch through one of the holes in the drive plate and allow it to rest against a projection on the engine block (automatic transaxle models).

i.3 Remove the flywheel/drive plate bolts from the crankshaft

4. Remove the flywheel/drive plate from thecrankshaft. Since the flywheel is fairly heavy, be sure to support it while removing the last bolt.

5. Clean the flywheel to remove greaseand oil. Inspect the surface for cracks, rivet grooves, burned areas and score marks. Light scoring can be removed with emery cloth. Check for cracked and broken ring gear teeth. Lay the flywheel on a flat surface and use a straightedge to check for warpage.

6. Clean and inspect the mating surfacesof the flywheel/drive plate and the crankshaft. If the rear main oil seal is leaking, replace it before reinstalling the flywheel/drive plate (see Rear main oil seal — replacement).

Installation

7. Position the flywheel/drive plate againstthe crankshaft. Note that some engines have an alignment dowel or staggered bolt holes to ensure correct installation. Before installing the bolts, apply thread-locking compound to the threads.

8. Prevent the flywheel/drive plate from turning by using one of the methods described in Step 3. Using a crisscross pattern, tighten the bolts to the torque listed in this Chapter’s Specifications.

9. The remainder of installation is thereverse of the removal procedure.