Anti-lock Brake System (ABS) and Vehicle Stability Assist (VSA) system — general information

General information

1. All models are equipped with an Anti-lock Brake System (ABS)/Vehicle Stability Assist (VSA) system. These systems are designed to maintain vehicle steerability, directional stability and optimum deceleration under severe braking and handling conditions. It does so by monitoring the rotational speed of each wheel and controlling the brake line pressure to each wheel during braking. This prevents the wheels from locking up.

2. If a problem develops within the system, an «ABS» or «VSA» warning light will glow on the dashboard. Sometimes, a visual inspection of the ABS or VSA can help you locate the problem. Carefully inspect the ABS or VSA wiring harness. Pay particularly close attention to the harness and connections near each wheel. Look for signs of chafing and other damage caused by incorrectly routed wires. If a wheel sensor harness is damaged, the sensor must be replaced.

Warning: Do NOT try to repair an ABS/ VSA wiring harness. The ABS/VSA system is sensitive to even the smallest changes in resistance. Repairing the harness could alter resistance values and cause the system to malfunction. If the ABS/VSA wiring harness is damaged in any way, it must be replaced.

Caution: Make sure the ignition is turned off before unplugging or reattaching any electrical connections.

Diagnosis and repair

3. If the dashboard warning light comes on and stays on while the vehicle is in operation, the system requires attention. Although special electronic diagnostic testing tools are necessary to properly diagnose the system, you can perform a few preliminary checks before taking the vehicle to a dealer service department.

- ) Check the brake fluid level in the reser

- ) Verify that the computer electrical connectors are securely connected.

- ) Check the electrical connectors at the hydraulic control unit.

- ) Check the fuses.

- ) Follow the wiring harness to each wheel and verify that all connections are secure and that the wiring is undamaged.

4. If the above preliminary checks do not rectify the problem, the vehicle should be diagnosed by a dealer service department or other qualified repair shop. Due to the complex nature of this system, all actual repair work must be done by a qualified automotive technician.

Wheel speed sensor — removal and installation

5. Loosen the wheel lug nuts, raise the vehicle and support it securely on jack stands. Remove the wheel.

6. Make sure the ignition key is turned to the Off position.

7. Trace the wiring back from the sensor, detaching all brackets and clips while noting its correct routing, then disconnect the electrical connector.

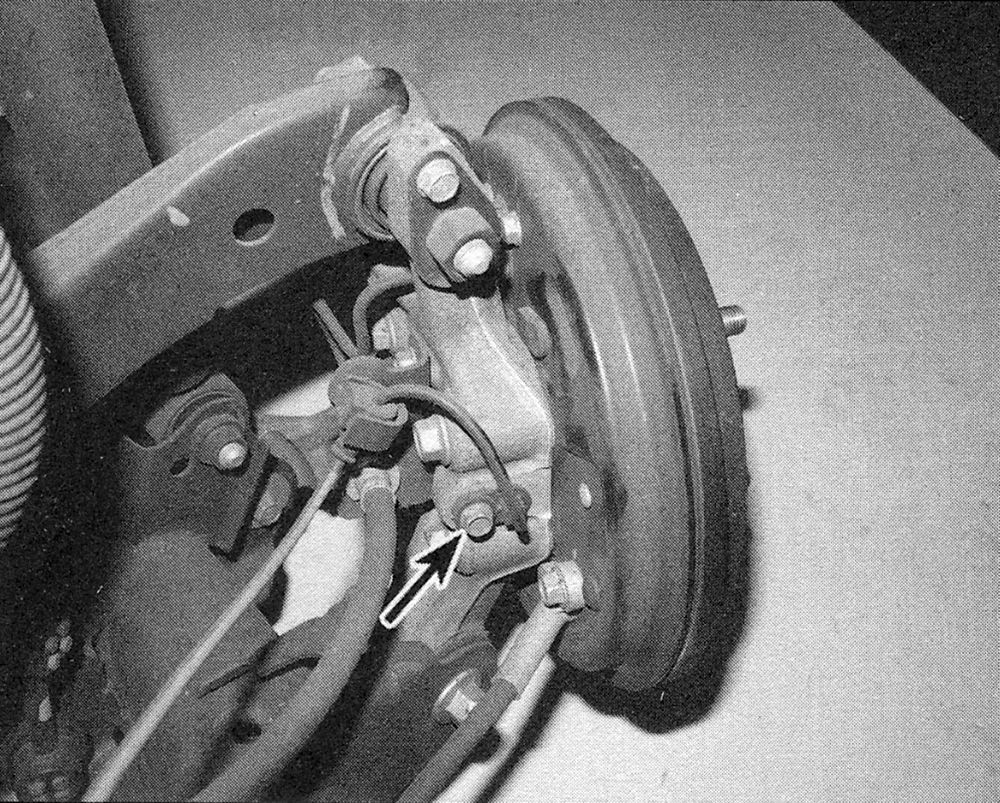

8. Remove the mounting bolt and carefully pull the sensor out from the knuckle or brake backing plate (see illustration).

i.8 Rear wheel speed sensor mounting bolt (front similar)

9. Installation is the reverse of the removal procedure. Tighten the mounting bolt securely.

10. Install the wheel and lug nuts, tightening them securely. Lower the vehicle and tighten the lug nuts to the torque listed in the Tune-up and routine maintenance Specifications.