Fluid level checks

1. Fluids are an essential part of the lubrication, cooling, brake, clutch and other systems. Because these fluids gradually become depleted and/or contaminated during normal operation of the vehicle, they must be periodically replenished. See Recommended lubricants and fluids and Capacities in this Chapter’s Specifications before adding fluid to any of the following components.

Note: The vehicle must be on level ground before fluid levels can be checked.

Engine oil

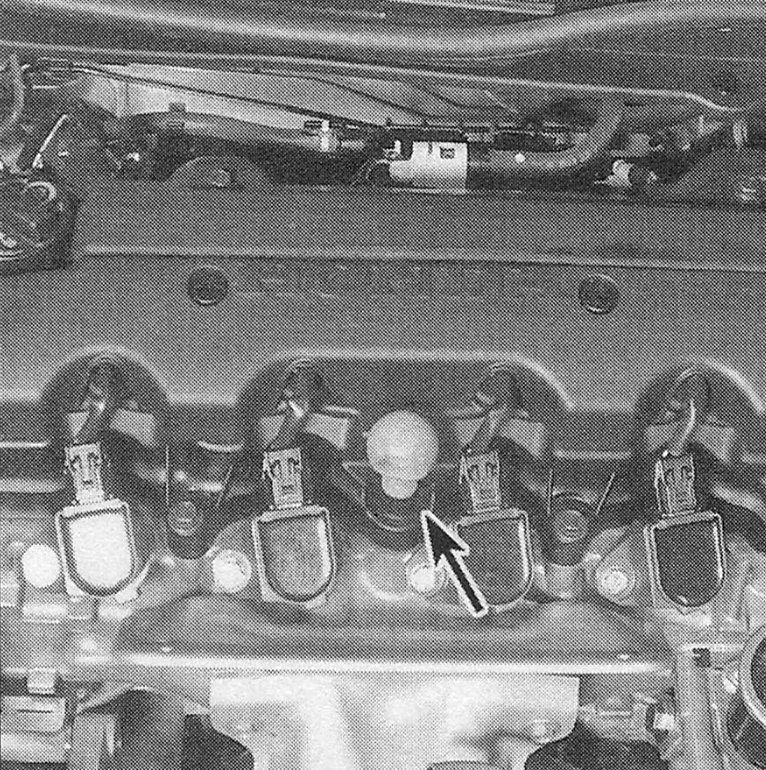

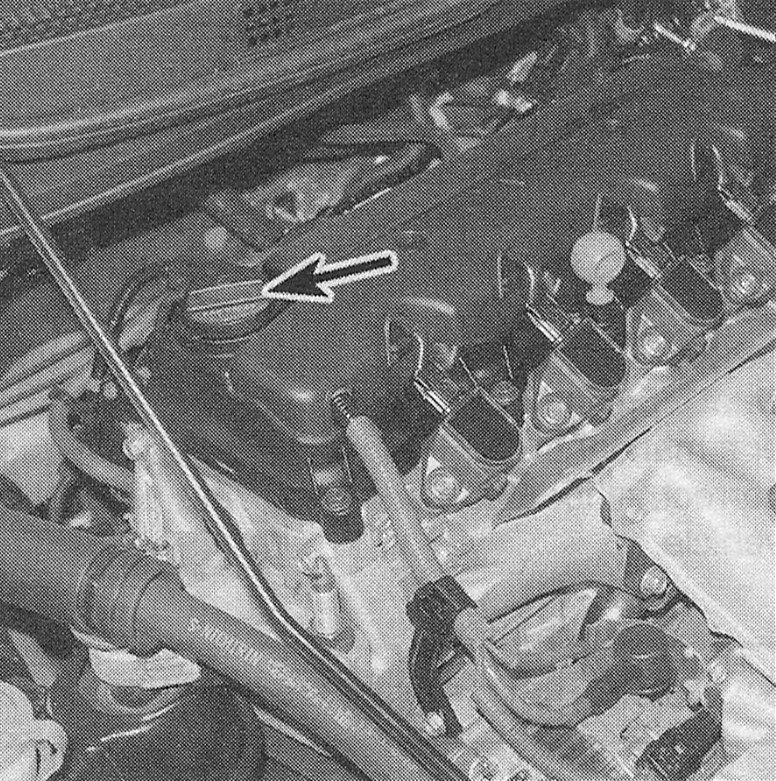

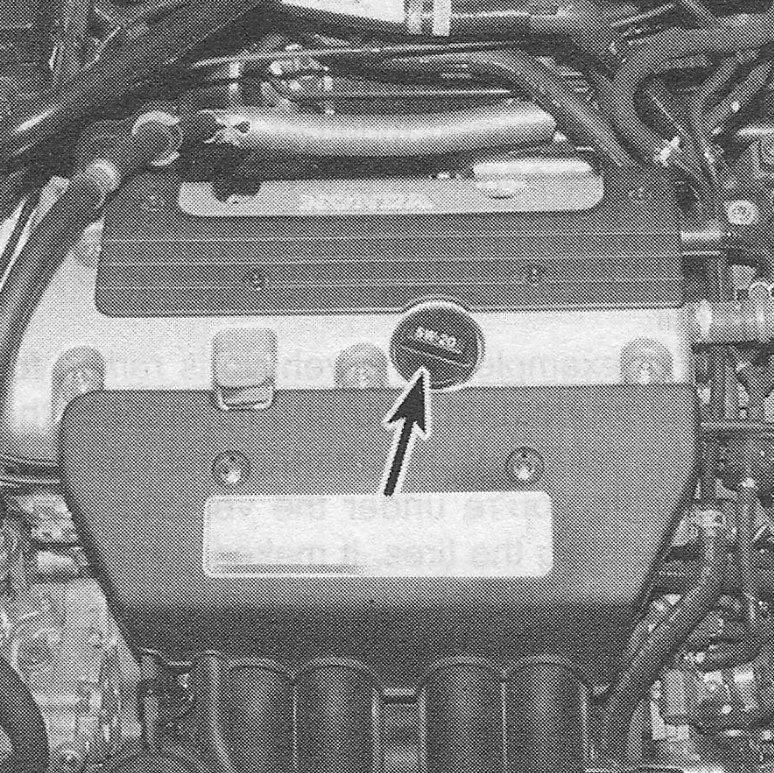

2. The engine oil level is checked with a dipstick located on top of the valve cover or a tube at the front side of the engine (see illustrations). The dipstick extends through the cylinder head or through a metal tube from which it protrudes down into the engine oil pan.

4.2a Engine oil dipstick location -1.8L engine

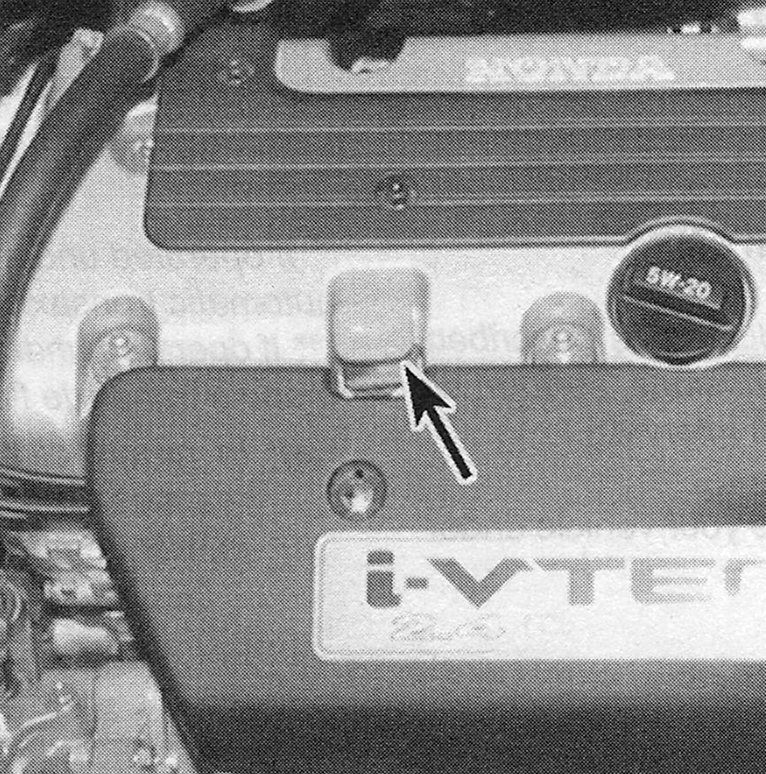

4.2b Engine oil dipstick location — 2.4L engine

3. The oil level should be checked before the vehicle has been driven, or about five minutes after the engine has been shut off. If the oil is checked immediately after driving the vehicle, some of the oil will remain in the upper engine components, producing an inaccurate reading on the dipstick.

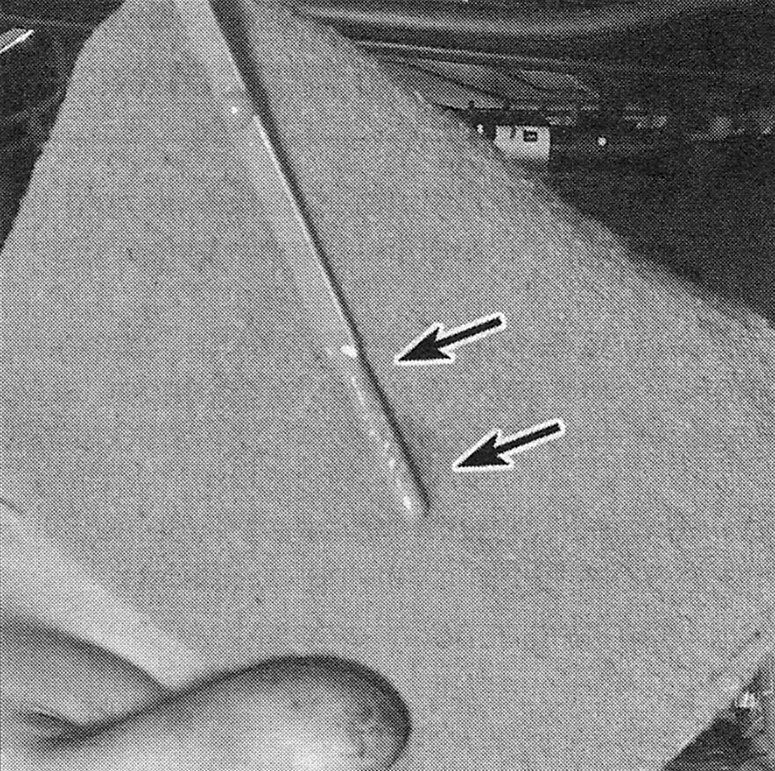

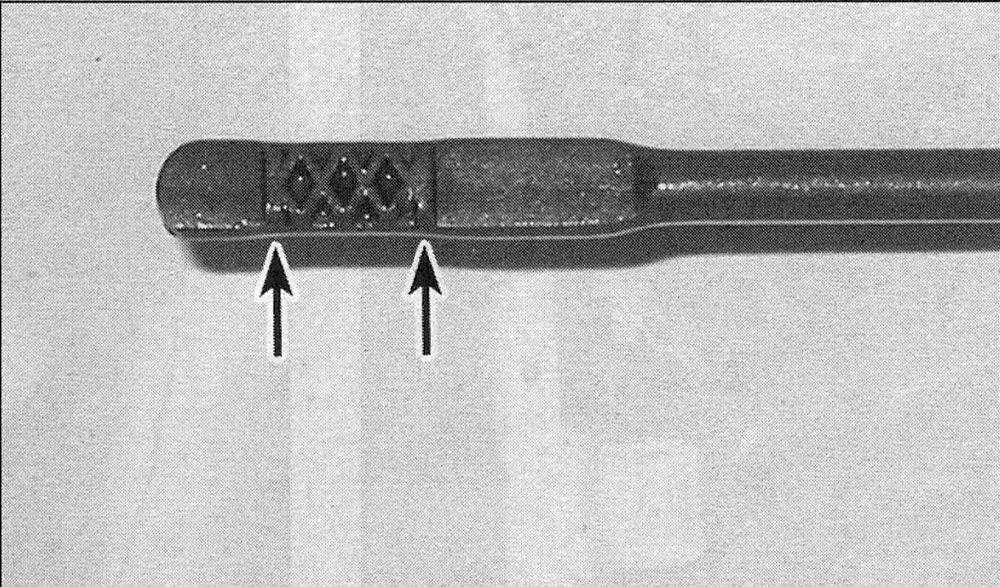

4. Pull the dipstick from the valve cover or tube and wipe all the oil from the end with a clean rag or paper towel. Insert the clean dipstick all the way back into its metal tube and pull it out again. Observe the oil at the end of the dipstick (see illustrations).

4.4a on 1.8L engines, the oil level should be in the crosshatched range on the dipstick (preferably near the top of the range)

4.4b on 2.4L engines, the oil level should be between the two holes (preferably near the upper hole)

5. It takes about one quart of oil to raise the level from the lower mark to the upper mark on the dipstick. Do not allow the level to drop below the lower mark or oil starvation may occur and cause engine damage. Conversely, overfilling the engine (adding oil above the upper mark) may cause oil fouled spark plugs, oil leaks, oil seal failures, or foaming of the oil (which will also result in inadequate lubrication and engine damage).

6. Remove the filler cap from the valve cover to add oil (see illustrations). Use a funnel to prevent spills. After adding the oil, install the filler cap hand tight. Start the engine and run it for about 30 seconds. Stop the engine and check the oil level again after it has had sufficient time to drain from the upper block and cylinder head galleys.

4.6a the oil filler cap is located on the valve cover — always make sure the area around the opening is clean before unscrewing the cap to prevent dirt from contaminating the engine (1.8L SOHC engine shown)

4.6b 2.4L engine oil filler cap location

7. Checking the oil level is an important preventive maintenance step. A continually dropping oil level indicates oil leakage through damaged seals, from loose connections, or past worn rings or valve guides. If the oil looks milky in color or has water droplets in it, a cylinder head gasket may be blown or the oil cooler could be leaking. The engine should be checked immediately. The condition of the oil should also be checked. Each time you check the oil level, slide your thumb and index finger up the dipstick before wiping off the oil. If you see small dirt or metal particles clinging to the dipstick, the oil should be changed (see Engine oil and oil filter change).

Engine coolant

Warning: Do not allow antifreeze to come in contact with your skin or painted surfaces of the vehicle. Flush contaminated areas immediately with plenty of water. Don’t store new coolant or leave old coolant lying around where it’s accessible to children or pets — they’re attracted by its sweet smell. Ingestion of even a small amount of coolant can be fatal! Wipe up garage floor and drip pan spills immediately. Keep antifreeze containers covered and repair cooling system leaks as soon as they’re noticed.

8. All vehicles covered by this manual are equipped with a pressurized coolant recovery system. A coolant reservoir is connected by a hose to the base of the radiator filler neck. If the coolant overheats, it can escape through the spring-loaded filler cap, then through the connecting hose into the reservoir. As the engine cools, the coolant is automatically drawn back into the cooling system to maintain the correct level.

9. The coolant level in the reservoir should be checked regularly. It must be between the MAX and MIN lines on the tank. The level will vary with the temperature of the engine. When the engine is cold, the coolant level should be at or slightly above the MIN mark on the tank. Once the engine has warmed up, the level should be at or near the MAX mark. If it isn’t, allow the fluid in the tank to cool, then remove the cap from the reservoir (see illustrations) and add coolant to bring the level up to the MAX line. Use only the recommended coolant and water in the mixture ratio listed in this Chapter’s Specifications. Do not use supplemental inhibitors or additives. If only a small amount of coolant is required to bring the shyster up to the proper level, water can be used. However, repeated additions of water will dilute the recommended antifreeze and water solution. In order to maintain the proper ratio of antifreeze and water, it is advisable to top up the coolant level with the correct mixture.

4.9a On Civic models, the coolant reservoir is located behind the radiator on the left side (on CR-V models it’s on the right side, behind the headlight)

4.9b Coolant reservoir MIN and MAX marks

Warning: Do not remove the radiator cap to check the coolant level when the engine is warm!

10. If the coolant level drops within a short time after replenishment, there may be a leak in the system. Inspect the radiator, hoses, engine coolant filler cap, drain plugs and water pump. If no leak is evident, have the radiator cap pressure tested.

Warning: Never remove the radiator cap or the coolant reservoir cap when the engine is running or has just been shut down, because the cooling system is hot. Escaping steam and scalding liquid could cause serious injury

11. If it is necessary to open the radiator cap, wait until the system has cooled completely, then wrap a thick cloth around the cap and turn it to the first stop. If any steam escapes, or you hear any hissing, wait until the system has cooled further, then remove the cap.

12. When checking the coolant level, always note its condition. It should be relatively clear. If it is brown or rust colored, the system should be drained, flushed and refilled. Even if the coolant appears to be normal, the corrosion inhibitors wear out with use, so it must be replaced at the specified intervals.

13. Do not allow antifreeze to come in contact with your skin or painted surfaces of the vehicle. Flush contacted areas immediately with plenty of water.

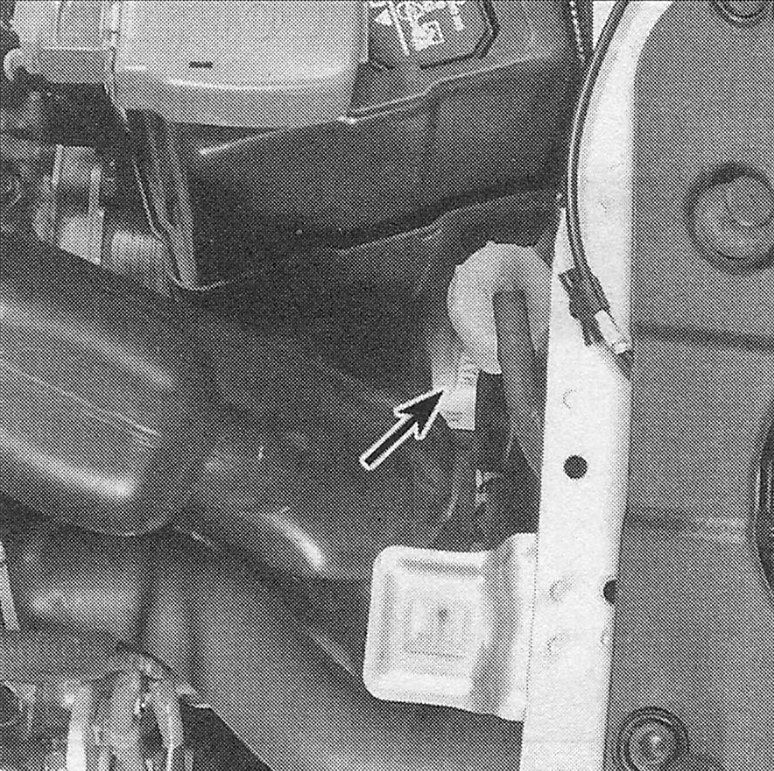

Windshield washer fluid

14. Fluid for the windshield washer system is stored in a plastic reservoir which is located in various locations depending on model and year (see illustration). In milder climates, plain water can be used to top up the reservoir, but the reservoir should be kept no more than 2/3 full to allow for expansion should the water freeze. In colder climates, the use of a specially designed windshield washer fluid, available at your dealer and any auto parts store, will help lower the freezing point of the fluid. Mix the solution with water in accordance with the manufacturer’s directions on the container. Do not use regular antifreeze. It will damage the vehicle’s paint.

4.14 Fluid for the windshield washer system is stored in this plastic reservoir (Civic model shown)

Brake and clutch fluid

15. The brake master cylinder is located on the driver’s side of the engine compartment firewall. The clutch master cylinder fluid reservoir is located right next to it on the firewall, behind the left shock tower. They both use the same type of fluid.

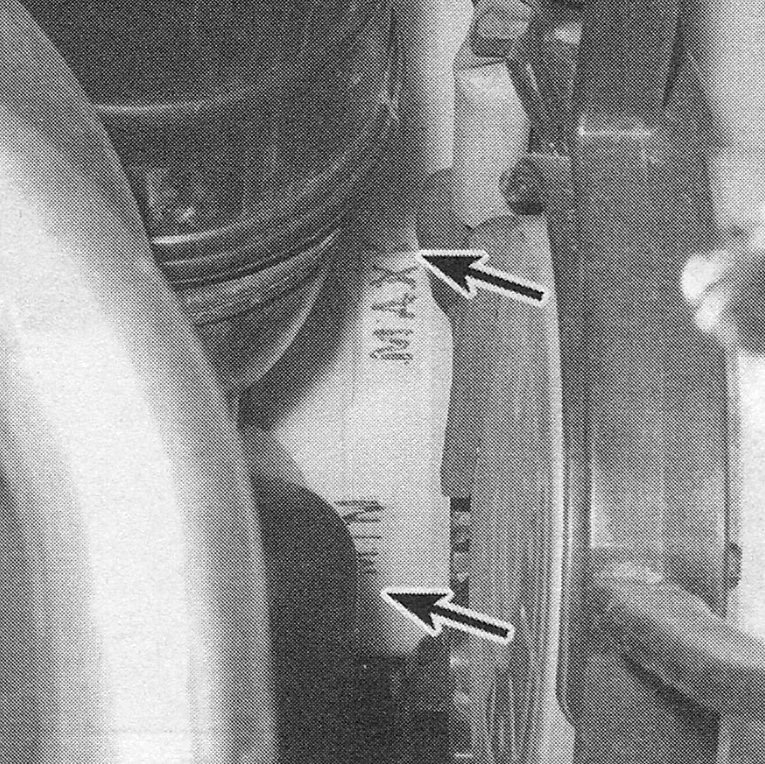

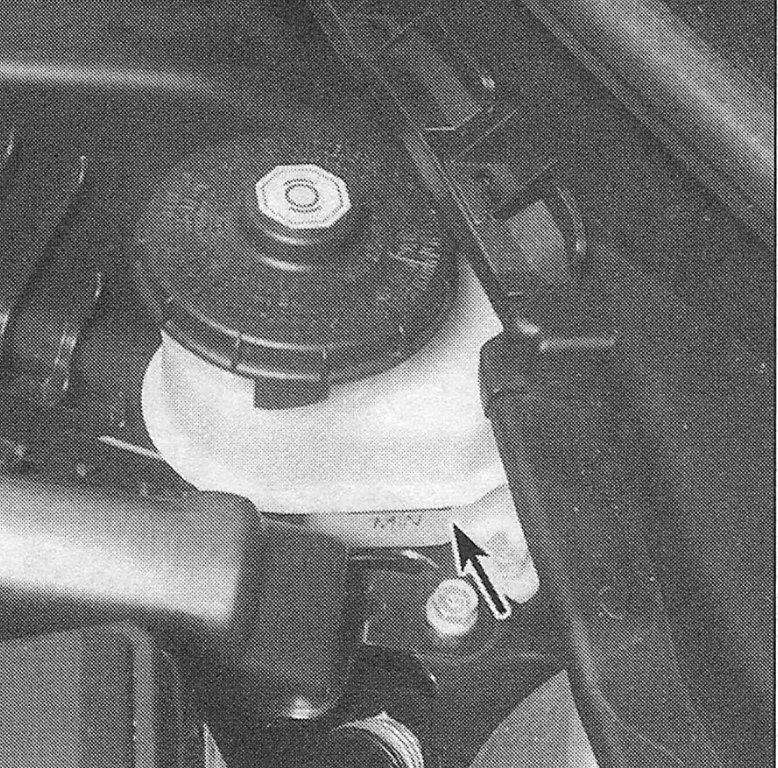

16. The level should be maintained between the MIN and MAX marks on the reservoir (see illustration).

4.16 The brake fluid level should be kept at the MAX mark on the translucent plastic reservoir

17. If additional fluid is necessary to bring the level up, use a rag to clean all dirt off the top of the reservoir. If any foreign matter enters the master cylinder when the cap is removed, blockage in the brake or clutch release system lines can occur. Also, make sure all painted

surfaces around the master cylinder are covered, since brake fluid will ruin paint. Carefully pour new, clean brake fluid into the master cylinder. Be careful not to spill the fluid on painted surfaces. Be sure the specified fluid is used; mixing different types of brake fluid can cause damage to the system. See Recommended lubricants and fluids at the beginning of this Chapter or your owner’s manual.

18. At this time the fluid and the master cylinder can be inspected for contamination. If deposits, dirt particles or water droplets are seen in the fluid, the system should be drained and refilled with fresh fluid (see Brake fluid change).

19. Reinstall the master cylinder cap.

20. The brake fluid in the master cylinder will drop slightly as the brake shoes or pads at each wheel wear down during normal operation. If the master cylinder requires repeated replenishing to keep the level up, it’s an indication of leaks in the brake system, which should be corrected immediately. Check all brake lines and connections, along with the wheel cylinders, if equipped, and booster (see Brakes for more information). As the clutch wears, the fluid level in the clutch master cylinder reservoir will rise. Unless there is a leak in either system, fluid additions shouldn’t be necessary.

21. If you discover that the reservoir is empty or nearly empty, the brake (or clutch) system should be filled, bled (see Brakes) and checked for leaks.

Automatic transaxle fluid

22. The level of the automatic transaxle fluid should be carefully maintained. Low fluid level can lead to slipping or loss of drive, while overfilling can cause foaming, loss of fluid and transaxle damage.

23. The transaxle fluid level should only be checked when the transaxle is hot (at its normal operating temperature). If the vehicle has just been driven over 10 miles (15 miles in a frigid climate), and the fluid temperature is 160 to 175-degrees F, the transaxle is hot. Caution: If the vehicle has just been driven for a long time at high speed or in city traffic in hot weather, or if it has been pulling a trailer, an accurate fluid level reading cannot be obtained. Allow the fluid to cool down for about 30 minutes.

24. If the vehicle has not just been driven, park the vehicle on level ground, set the parking brake and start the engine. While the engine is idling, depress the brake pedal and move the selector lever through all the gear ranges, beginning and ending in Park.

Automatic transaxle (non-CVT models)

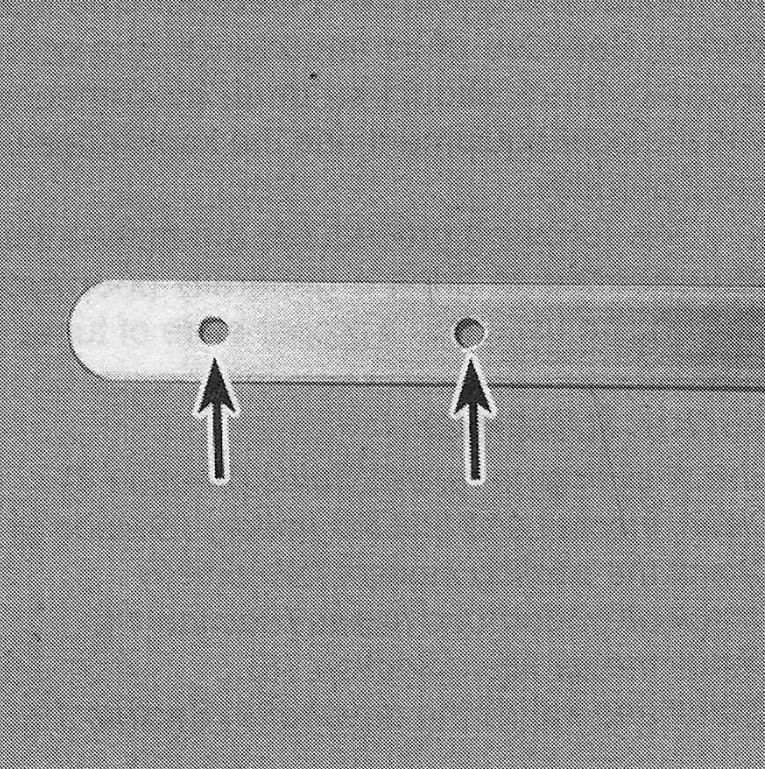

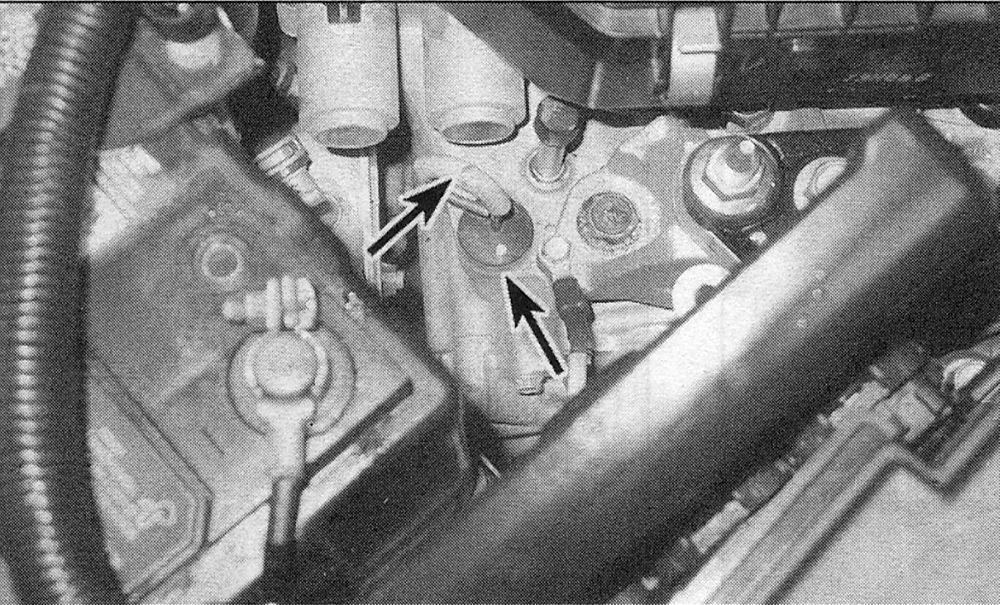

25. With the engine still idling, remove the dipstick from its tube. Check the level of the fluid on the dipstick and note its condition (see illustrations).

4.25a the automatic transaxle dipstick is located on the left side

4.25b the automatic transaxle fluid level should be in the cross- hatched area on the dipstick

26. Wipe the fluid from the dipstick with a clean rag and reinsert it back into the filler tube until the cap seats.

27. Pull the dipstick out again and note the fluid level. The fluid level should be in the operating temperature range (between the upper and lower mark). If the level is at the low side of either range, add the specified automatic transmission fluid through the dipstick tube with a funnel.

28. Add just enough of the recommended fluid to fill the transaxle to the proper level. It takes about one pint to raise the level from the low mark to the high mark when the fluid is hot, so add the fluid a little at a time and keep checking the level until it is correct.

29. The condition of the fluid should also be checked along with the level. If the fluid at the end of the dipstick is black or a dark reddish-brown color, or if it emits a burned smell, the fluid should be changed (see Automatic transaxle fluid change). If you are in doubt about the condition of the fluid, purchase some new fluid and compare the two for color and smell.

Automatic Continuously Variable Transmission (CVT) models

Note: It isn’t necessary to check this fluid weekly — every 15,000 miles (24,000 km) or 12 months will be adequate (unless a fluid leak is noticed).

30. A dipstick is available on some 2.4L engine models. If the CVT is equipped with a dipstick, see Steps 25 through 29.

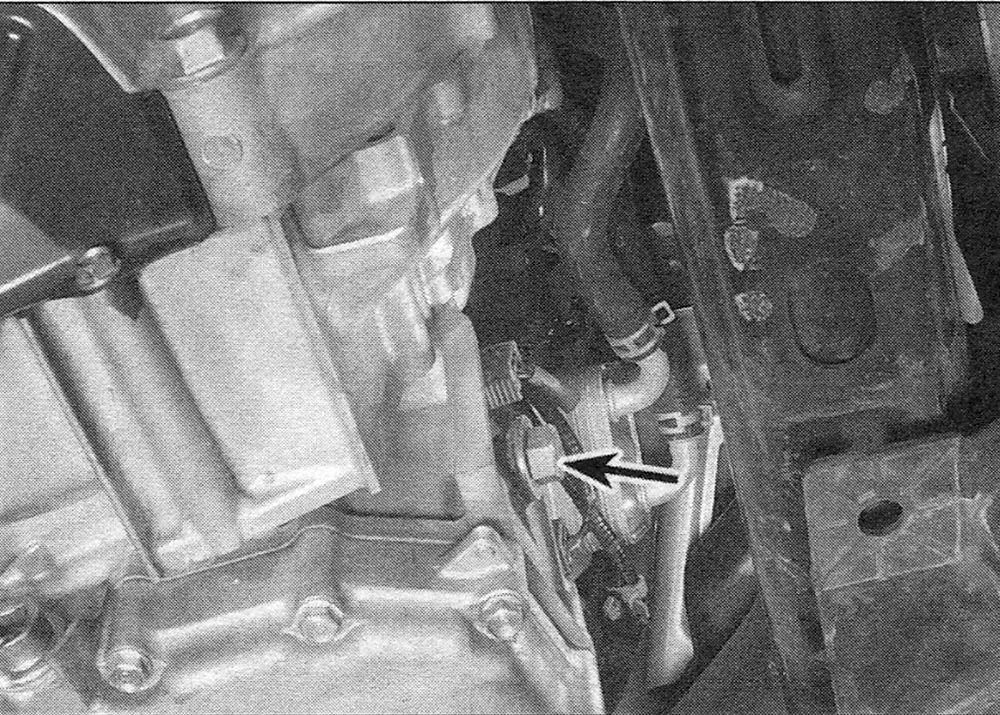

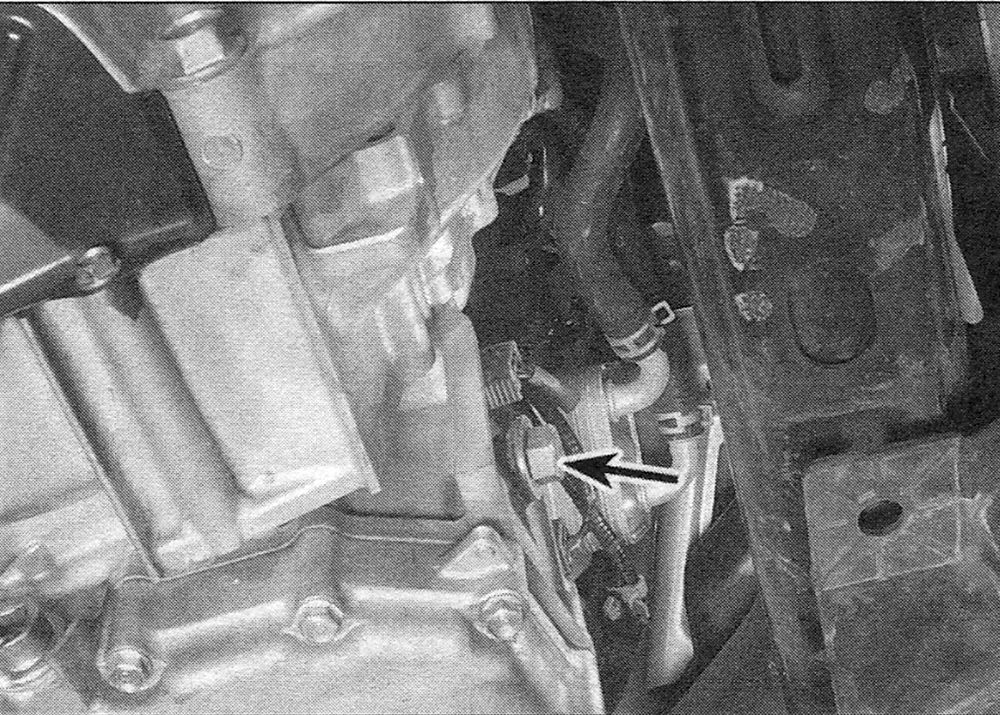

31. On other models, the CVT transaxle does not have a dipstick. To check the fluid level, raise the vehicle and support it securely on jack stands. On the front side of the transaxle housing, remove the fluid check plug (see illustration). If the fluid level is correct, it should just drip from the hole.

4.31 Location of the CVT transaxle fluid check plug

Note: Both ends of the vehicle should be raised and supported on jack stands for an accurate check.

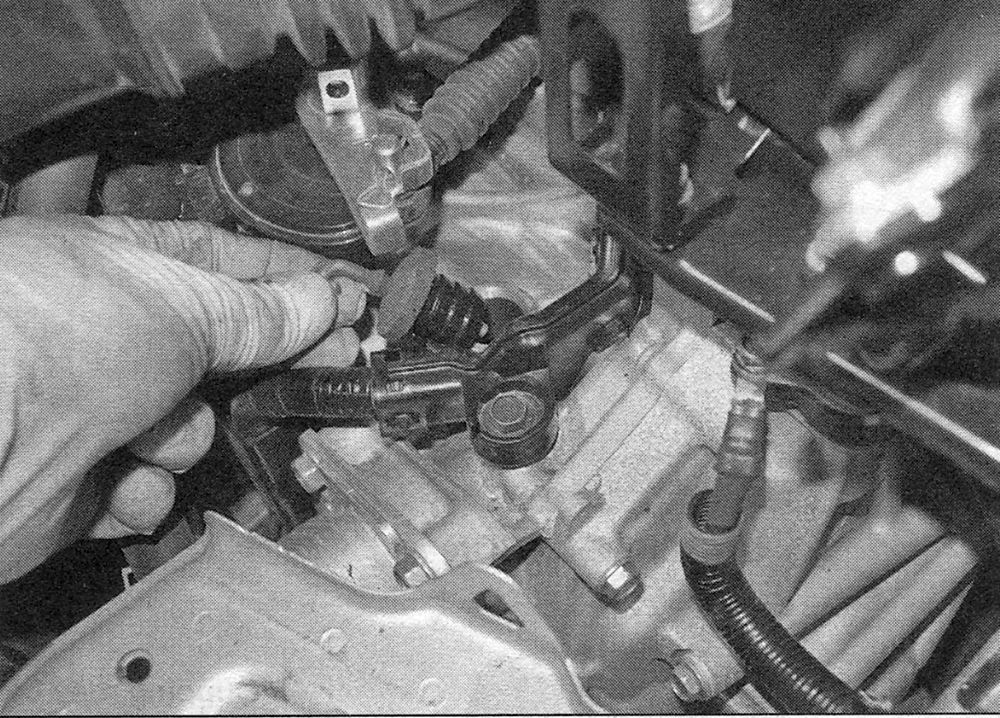

32. If the transaxle needs more fluid (if the fluid doesn’t trickle out of the hole), you can either use a pump to add more through the check hole, or remove the fill plug at the top of the transaxle and add the fluid there (see illustrations). Stop filling the transaxle when the lubricant begins to run out the hole. Allow the fluid to flow from the hole until it just drips out.

4.32a A hose and fluid pump can be used to add fluid through the check hole…

4.32b… or fluid can be added to the fill hole at the top of the transaxle case (battery removed for clarity)

33. Install the plug and tighten it to the torque listed in this Chapter’s Specifications. Drive the vehicle a short distance, then check for leaks.

34. The condition of the fluid should also be checked along with the level. If the fluid is black or a dark reddish-brown color, or if it emits a burned smell, the fluid should be changed (see Automatic transaxle fluid change). If you are in doubt about the condition of the fluid, purchase some new fluid and compare the two for color and smell.

Manual transaxle lubricant

Note: It isn’t necessary to check this lubricant weekly; every 15,000 miles (24,000 km) or 12 months will be adequate.

35. The manual transaxle does not have a dipstick. To check the fluid level, raise the vehicle and support it securely on jack stands. On the left end of the transaxle housing, remove the check/fill plug. If the lubricant level is correct, it should be up to the lower edge of the hole.

36. If the transaxle needs more lubricant (if the level is not up to the hole), use a syringe or a gear oil pump to add more through the hole. Stop filling the transaxle when the lubricant begins to run out the hole.

37. Install the plug and tighten it to the torque listed in this Chapter’s Specifications. Drive the vehicle a short distance, then check for leaks.

Rear differential lubricant (CR-V)

Note: It isn’t necessary to check this lubricant weekly; every 15,000 miles (24,000 km) or 12 months will be adequate.

38. To check the fluid level, raise the vehicle and support it securely on jack stands. On the axle housing, remove the check/fill plug. If the lubricant level is correct, it should be up to the lower edge of the hole.

39. If the differential needs more lubricant (if the level is not up to the hole), use a syringe or a gear oil pump to add more. Stop filling the differential when the lubricant begins to run out the hole.

40. Install the plug and tighten it securely. Drive the vehicle a short distance, then check for leaks.