Steering, suspension and driveaxle boot check

Note: For detailed illustrations of the steering and suspension components, refer to Chapter Suspension and steering.

With the wheels on the ground

1. With the vehicle stopped and the front wheels pointed straight ahead, rock the steering wheel gently back and forth. If free play is excessive, a front wheel bearing, steering shaft universal joint or lower arm ball joint is worn or the steering gear is out of adjustment or broken. Refer to Chapter Suspension and steering for the appropriate repair procedure.

2. Other symptoms, such as excessive vehicle body movement over rough roads, swaying (leaning) around corners and binding as the steering wheel is turned, may indicate faulty steering and/or suspension components.

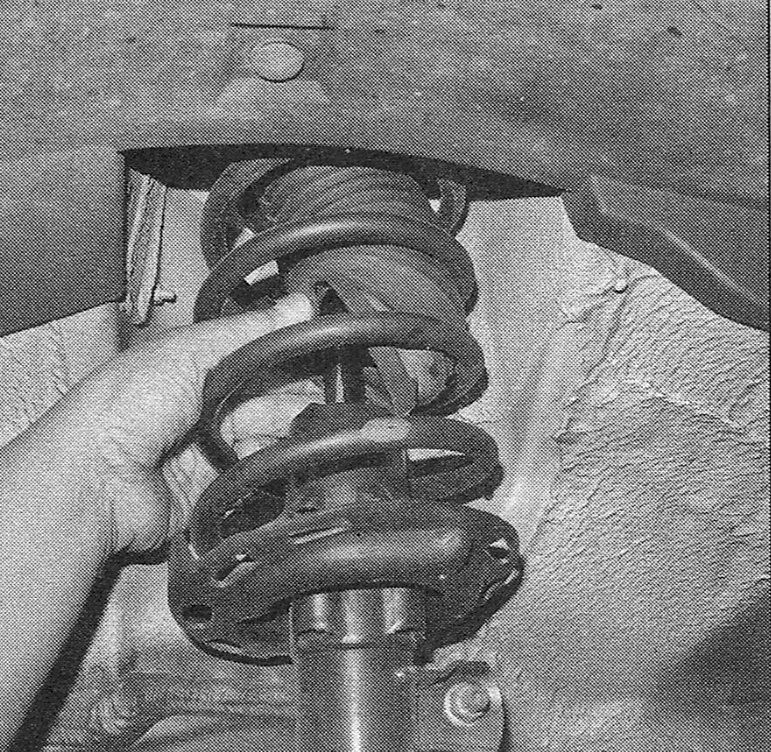

3. Check the shock absorbers by pushing down and releasing the vehicle several times at each corner. If the vehicle does not come back to a level position within one or two bounces, the shocks/struts are worn and must be replaced. When bouncing the vehicle up and down, listen for squeaks and noises from the suspension components.

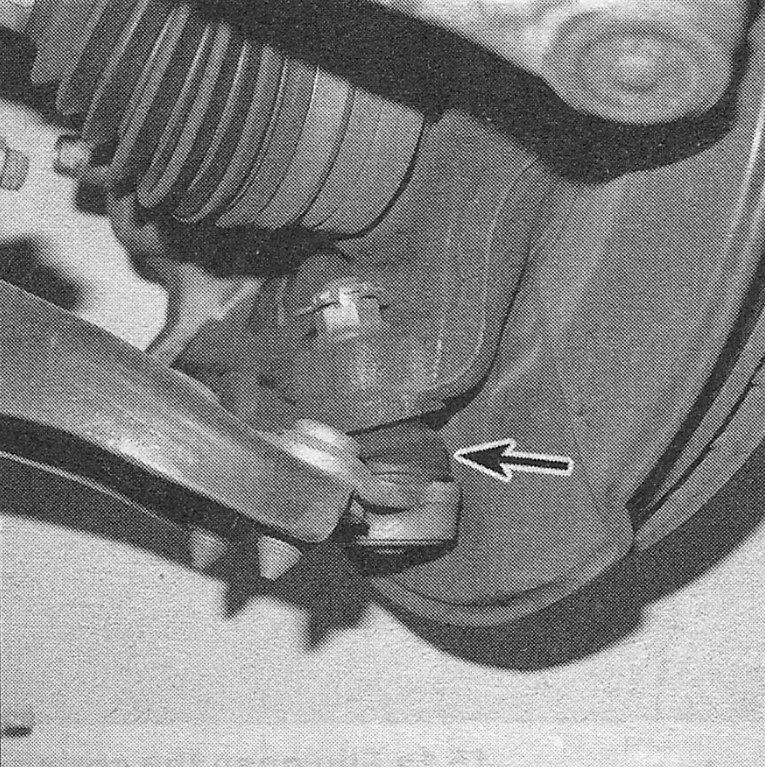

4. Check the struts and shock absorbers for evidence of fluid leakage (see illustration). A light film of fluid is no cause for concern. Make sure that any fluid noted is from the shocks and not from some other source. If leakage is noted, replace the shocks as a set.

i.4 Check the shocks for leakage at the indicated area

5. Check the shocks to be sure they are securely mounted and undamaged. Check the upper mounts for damage and wear. If damage or wear is noted, replace the shocks as a set (front and rear).

6. If the shocks must be replaced, refer to Chapter Suspension and steering for the procedure.

Under the vehicle

7. Raise the vehicle with a floor jack and support it securely on jack stands. See Jacking and towing at the front of this book for the proper jacking points.

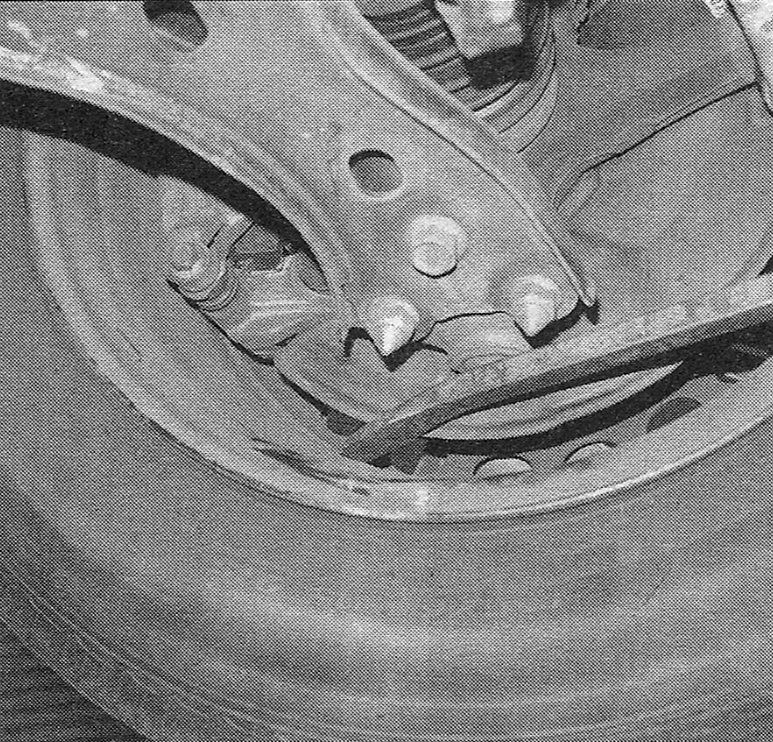

8. Check the tires for irregular wear patterns and proper inflation. See Tire and tire pressure checks for information regarding tire wear and Chapter 10 for information on hub bearing replacement.

9. Inspect the universal joint between the steering shaft and the steering gear housing. Check the steering gear housing for lubricant leakage. Make sure that the dust seals and boots are not damaged and that the boot camps are not loose. Check the steering linkage for looseness or damage. Check the tie-rod ends for excessive play. Look for loose bolts, broken or disconnected parts and deteriorated rubber bushings on all suspension and steering components. While an assistant turns the steering wheel from side to side, check the steering components for free movement, chafing and binding. If the steering components do not seem to be reacting with the movement of the steering wheel, try to determine where the slack is located.

10. Check the ball joints for wear by trying to move each control arm up and down with a pry bar (see illustration) to ensure that its ball joint has no play. If any ball joint does have play, replace it. See Chapter Suspension and steering for the ball joint replacement procedure.

i.10 To check the ball joint for wear, try to pry the control arm up and down to make sure there is no play in the ball joint

(if there is, replace it)

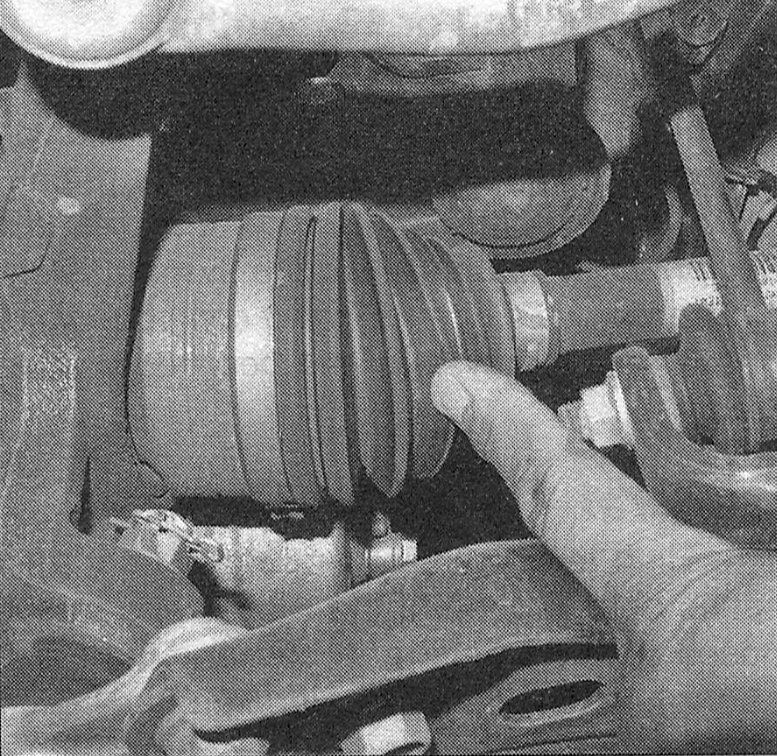

11. Inspect the ball joint boots for damage and leaking grease (see illustration). Replace the ball joints with new ones if they are damaged (see Suspension and steering).

i.11 Check the ball joint boot for damage

12. At the rear of the vehicle, inspect the suspension arm bushings for deterioration. Additional information on suspension components can be found in Chapter Suspension and steering.

Drive axle boot check

Note: For detailed illustrations of the drive axles, refer to Clutch and driveline.

13. The drive axle boots are very important because they prevent dirt, water and foreign material from entering and damaging the constant velocity (CV) joints. Oil and grease can cause the boot material to deteriorate prematurely, so it’s a good idea to wash the boots with soap and water. Because it constantly pivots back and forth following the steering action of the front hub, the outer CV boot wears out sooner and should be inspected regularly.

14. Inspect the boots for tears and cracks as well as loose clamps (see illustration). If there is any evidence of cracks or leaking lubricant, they must be replaced as described in Chapter Clutch and driveline.

i.14 Flex the drive axle boots by hand to check for cracks and/or leaking grease